02 March 2023

All about drills and bits – and more: Part 2 – drill bits

Last month we took you through the various types of drills you are most likely to find on the market and most likely to require at some stage or other for tasks around the home and in the workshop. Now to the drill bits themselves…

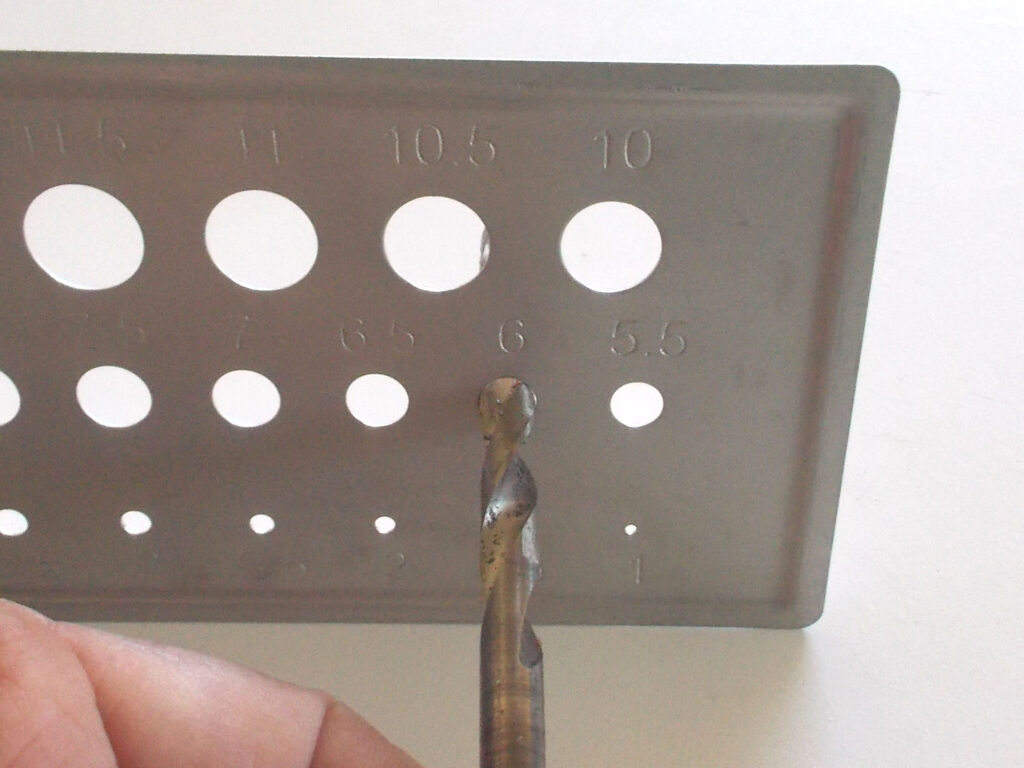

- To begin with, a very useful item to have is a drill bit measuring plate such as this one. It is used to establish the diameter of any drill bit ranging from 13mmØ down to 1mmØ – useful when you have a number of drill bits that have hard-to-read size indicators or for which the packaging in which they came has long gone.

- The plate is easy to use. Take the drill bit and insert it into the nearest size holes. If it doesn’t fit in one, go to the next size up and see if it fits there. If not, up one again. If it was loose in the first hole, try the next smaller hole.

- In this case, it passed easily into the 6.5mmØ hole, with some play, but was just too large a diameter to pass into the 5.5mmØ hole.

- So it was a 6mmØ drill bit. Success! Note: You could conceivably use a drill measuring plate to check the diameter of a masonry bit, but ensure that you measure across the tungsten-carbide inserts at the tip of a masonry bit – and not the shaft (also sometimes referred to at the shank) as the tungsten-carbide inserts often stand proud the shank diameter.

- A range of Titanium Nitride-coated (TiN) High-Speed Steel (HSS) ranging in size from 1mmØ up to 10mmØ. HSS bits are a popular choice for drilling into soft metals such as steel, aluminium, brass or copper, and into wood, plastic and fibreglass. Drill bits of this type are sometimes referred to a twist drill bit or fluted drill bit, as they have flutes which are designed to remove material from the drill hole.

- The parts of a typical HSS drill bit. Nomenclature can possibly vary from one manufacturer to another, but the basics are all the same. The point is self-evident – that’s the part that does all the hard work. The flute removes loose material created by the tip from the hole. The land is a slightly raised portion of the body, so that there is a little clearance between the hole being drilled and the body of the drill bit (the body clearance). This ensures that the shaft/shank is able to rotate freely in the hole being drilled without adding a frictional impediment to the bit’s rotation. The tang, or course, is the part of the shaft/shank that is gripped in the drill’s chuck.

- A little more detail on the actual tip. A very common angle for the point angle is 118°. The part behind the cutting lip is its flank and the part of the bit immediately below it is the face.

- An assortment of stubby double-ended drill bits. They can cost a little more, but as you can see you get double the use out of them. These HSS bits are often used to drill through extruded aluminium and sheet metal as they do not drill very deep holes. Typical sizes range from 2mmØ up to 6mmØ.

- When seating a stubby bit, use the marking at the midpoint to correctly set the drill in the chuck – the jaws of which should NEVER be clamped on to the cutting section – the flutes – as not only could the bit tend to be clamped at a slight angle, but the flutes will be damaged.

- Stubby bits are usually sold in packs, ranging up to about 10 pieces when in the smaller diameters – when you consider you are getting an effective 20 bits in a packet of 10, it can be a rather good deal – bearing in mind, of course the point made just above about the depth of hole these bits can be used to drill.

- Drill sets – in this case from 10mmØ down to 1mmØ in increments of 1mm – are available in a range of drill types and size ranges.

- These screw pilot sets are available in sets of 4 or 5 and bits are not sold individually, so if you break one, you will need to buy another set. Having said that, they are not expensive and are good value for money. Their tangs are of sintered metal pressed into a hexagonal cross-section of 6.35mmØ. (Sintering [also known as frottage] is the process of forming a solid mass of material by compacting it under pressure or heat without melting it to a liquid state]). Their tang shape makes them very useful drill bits for use with cordless drill drivers, but obviously, can also be used with mains-powered machines. Their sizes are as follows for the four-pack:

#6 (screw gauge) x 2.3mmØ drill

#8 (screw gauge) x 2.8mmØ drill

#10 (screw gauge) x 3.0mmØ drill

#12 (screw gauge) x 3.6mmØ drill

The pack of five has bits with the following diameters:1.5mmØ, 2.5mmØ, 3mmØ, 4mmØ and 5mmØ. The four symbols on the packaging indicate that these bits are suitable for use on copper (Cu), Nickel (Ni), Zinc (Zi) and Mild steel (Ms). However, they are also suitable for use on aluminium, wood, plastic and fibreglass.

#6 (screw gauge) x 2.3mmØ drill

#8 (screw gauge) x 2.8mmØ drill

#10 (screw gauge) x 3.0mmØ drill

#12 (screw gauge) x 3.6mmØ drill

The pack of five has bits with the following diameters:1.5mmØ, 2.5mmØ, 3mmØ, 4mmØ and 5mmØ. The four symbols on the packaging indicate that these bits are suitable for use on copper (Cu), Nickel (Ni), Zinc (Zi) and Mild steel (Ms). However, they are also suitable for use on aluminium, wood, plastic and fibreglass.

- #6 (screw gauge) x 2.3mmØ drill

- #8 (screw gauge) x 2.8mmØ drill

- #10 (screw gauge) x 3.0mmØ drill

- #12 (screw gauge) x 3.6mmØ drill

- The pack of five has bits with the following diameters:1.5mmØ, 2.5mmØ, 3mmØ, 4mmØ and 5mmØ. The four symbols on the packaging indicate that these bits are suitable for use on copper (Cu), Nickel (Ni), Zinc (Zi) and Mild steel (Ms). However, they are also suitable for use on aluminium, wood, plastic and fibreglass.

- Just to give you an idea of the range of sizes of drill bits, here is a 16mmØ bit alongside a 0.8mmØ bit. In passing, note that the large bit has a reduced tang, so be careful not to fit it into a drill a lower power rating than a 16mmØ bit requires – such as a drill with a 13mmØ chuck; you could strain the drill.

- A selection of brad bits, ranging in size from 10mmØ, and then down through 8mmØ, 7mmØ, 6mmØ, 5mmØ, 4mmØ and 3mmØ. Whereas twist drill bits, such as HSS, can be used on wood as well as metals, brad bits are intended for use ONLY on wood and some types of plastic.

- A close-up of a brad bit tip. The central spur allows for very precise positioning of the bit and the very sharp cutting lips are designed to produce a very clean-edged hole in soft and hard woods.

- The parts of a brad drill bit.

- A selection of smooth shank masonry drill bits ranging in this image from 8mmØ, 7mmØ, 6mmØ, 5.5mmØ, 5mmØ, 4mmØ, and 3mmØ.

- A close-up of the tip of one of these bits. Note how the tungsten-carbide cutting edge protrudes beyond the fluted shank. This ensures that the shank does not bind in the hole being drilled.

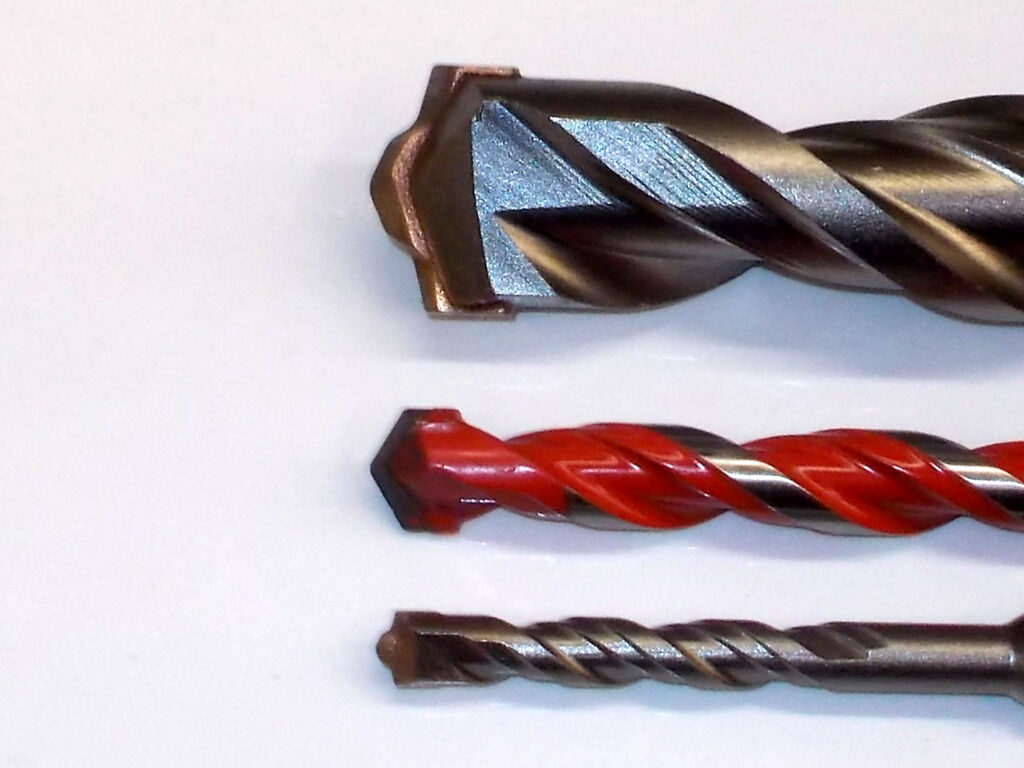

- Two masonry bits, but this time with SDS heads, for fitting to a rotary hammer – discussed in the first part of this series on types of drills. SDS stands for Slotted Drive Shaft or Slotted Drive System.

- A close-up of the two heads, shaped to lock into a rotary hammer drill chuck. These drill bits cannot be used in a drill fitted with the 3-jawed chuck (which is designed for use with drill bits with either smooth shanks or hexagonal tangs.

- Three masonry bits – 24mmØ (top), 12mmØ (centre) and 8mmØ (bottom). Note that the bit in the centre has a smooth shank while those on either side have SDS heads.

- A close-up of the three drills’ tips. Note that in each case the tungsten-carbide inserts extend slightly beyond the drill shaft’s diameter so that the hole being drilled is slightly larger than the shaft itself, ensuring no binding will occur.

- A selection of three spade bits 16mm, 22mm and 32mm. Spade bits range in size from 6mm up to 40mm or so and are intended for use ONLY on wood, though they can be used – very carefully – to drill through certain plastics, such as Perspex. Shank lengths are generally 150mm, but longer versions – up to 400mm long – are available and are useful, for example, when drilling down the length of a piece of timber when a bit with a 150mm shank will not drill right through in one pass. Extenders are also available for these bits and can be used with either the shorter 150mm bit or the longer 400mm bit.

- The parts of a spade bit. The centre point acts as a guide to stop the bit wandering off course and the lips do bulk of the work in removing material from the bottom of the hole being drilled. In this case, the shank is hexagonal, which increases the chuck’s ‘grip’. The cable hole is used to pull electrical wiring out through holes drilled in dry walls, but many if not most users find the cable hole is handy when hanging the bit on a panel pin a vertical surface for storage.

- An illustration of a spade bit with spurs. They are designed to cut cleanly through the wood and usually produce a much cleaner, neater edge to the drilled hole.

Next month, more on drill bits and some hints and tips on getting the best out of them (and correcting an error or two you made while drilling a hole)

Panel:

Mica Stores carry a range of power drills, hand drills and bits and accessories. To find your closest Mica and whether or not they stock the items required, please go to www.mica.co.za, find your store and call them. If your local Mica does not stock exactly what you need they will be able to order it for you or suggest an alternative product or a reputable source.